one-key flash test 190 series

one-key flash test 190 series

one-key flash test vertical series

one-key flash test vertical series

one-key flash test splicing series

one-key flash test splicing series

one-key flash test horizontal series

one-key flash test horizontal series

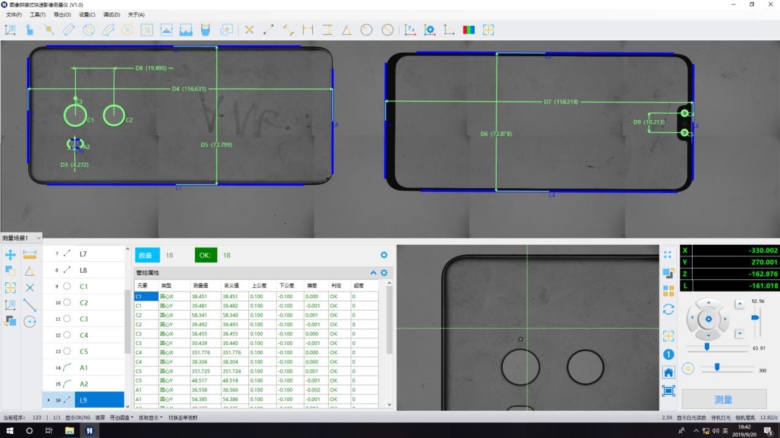

Automatic matching workpiece, arbitrary placement, one key measurement. It can automatically search for matches and call up the user program. Matching can be established by frame selection, multi position frame selection combination, measurement element and CAD. The program group can be established to realize the measurement of multiple parts.

lBreak with traditional measurement tools

lLarge aperture and high depth of field, to achieve clear imaging in the entire field of view without distortion;

lThe software adopts advanced 20:1 sub-pixel image edge processing;

l Efficient batch measurement range can measure more than 20,000 sizes at one time, and the measurement time for 100 sizes is less than 1 second, which greatly shortens the measurement time and improves the measurement efficiency;

l Accurate flash test, which will be triggered at any moment;

l Arbitrary placement of multiple workpieces, automatic identification, batch measurement;

l High-resolution cameras, adopting high-resolution digital cameras with 12 to 43 million pixels;

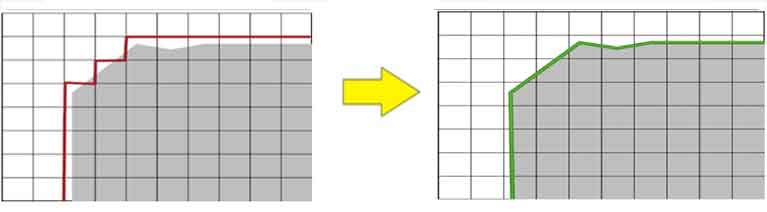

l Least squares regression processing can automatically remove burrs and abnormal points, minimizing the impact on feature positions

l Automatic image matching function, measurement workpieces can be placed arbitrarily, no positioning fixtures, no focus adjustment, no manual operation of the stage;

l It can realize the measurement of multiple positions of the workpiece, increase the measurement size, and it will not consume more measurement time;

l Multiple workpieces can be measured at the same time, without a single measurement for each workpiece;

l Simple operation, can quickly complete all measurement processes, and output measurement results;

l The image is focused clearly within 2 seconds, with high consistency of repeated focusing and zero errors;

l The measurement is accurate, and the measurement results will not vary from person to person;

l The measurement process does not require platform movement, which effectively prevents measurement errors caused by product displacement;

l Anti-vibration platform design and integrated structure to ensure the rigidity of the instrument;

l The ergonomic design allows the surveyor to have a comfortable measuring space;

l The measurement results can be automatically saved to the host;

Model | KX-322CNC | KX-432CNC | KX-542CNC |

Measuring stroke (mm) | 300×200×200 | 400×300×200 | 500×400×200 |

Machine movement method | automatic | automatic | automatic |

Single field of view measurement range (mm) | 86×57 | 86×57 | 86×57 |

Optical lens | Double telecentric optical lens | Double telecentric optical lens | Double telecentric optical lens |

Depth of field (mm) | 150 | 150 | 150 |

Image sensor (pixels) | 200 M | 200 M | 200 M |

Platform movement measurement accuracy (μm) | ±(3.0+L/200) | ±(3.0+L/200) | ±(3.0+L/200) |

Measurement accuracy when the platform is not moved (μm) | ±2.0 | ±2.0 | ±2.0 |

Repeatability (μm) | ±2.0 | ±2.0 | ±2.0 |

light source | 1000-level programmable light source Contour light: telecentric parallel light Surface light: LED ring light/coaxial light | ||

Image Processing | IVT advanced image analysis method, 256 gray levels, 20:1 sub-pixel processing technology | ||

Software | TAIWAN VISION | ||

Minimum display unit (μm) | 0.01 | ||

Dimensions (mm) | 1170x700x1707 | 1170x700x1707 | 1353x886x1707 |

Weight (KG) | 280 | 300 | 400 |

Weight Bearing (KG) | 20 | ||

Working Environment | Power supply: 220V/50Hz Vibration:<0.002mm/s, <15Hz Temperature: 22℃±5℃ Humidity: 20~80% | ||

1 | Host | 1 | Host | One-piece body and base (automatic splicing) |

2 | Camera system | 20 million class high-definition camera | ||

3 | Lens | Double telecentric large field of view optical lens | ||

4 | Measuring range | 86*57mm (single field of view) 86*57+20*15mm (dual field of view) | ||

5 | Measurement Accuracy | Splicing accuracy 3.0+L/200μm Single field of view accuracy 2.0μm | ||

6 | Motor | Three-axis servo motor and driver | ||

7 | Controller | Dedicated measurement controller | ||

8 | Light Source | Parallel contour light + surface light (automatic lighting and fill light) | ||

2 | Computer System | 1 | Computer | AOC computer (I7-9700/16G processor/500G/23.8 inch LCD monitor) |

3 | Software System | 1 | Basic Software | Taiwan VISION dedicated measurement software |

Remarks:

① Special models and software functions can be customized

② Optional laser measurement of three-dimensional size

③ Optional double magnification + double camera

④ Optional low-angle automatic lifting zone light source

1. User program:

Automatically match the workpiece, place it arbitrarily, and measure with one button. Can automatically search for matches and call out user programs. Frame selection can be used to establish a match, multiple position frame selection combinations can be used to establish a match, measurement elements can be used to establish a match, and CAD can be imported to establish a match. Program groups can be created to realize the measurement of multiple sides of the workpiece.

2. Comprehensive measurement elements:

Point, highest point, line, highest line, circle (center coordinates, radius, diameter, roundness, circumference, area, maximum radius, minimum radius), arc, rectangle (center coordinates, length, width, circumference, area) ), ellipse (center coordinates, major axis, minor axis, circumference, area), keyway (center coordinates, length, width, circumference, area), import CAD contour scan comparison, contour PV, area comparison, cylindrical diameter, Sealing ring (calculate the radius from the circumference, the maximum radius of the sealing ring, the minimum radius, the thickness), the measurement result recalculation (maximum, minimum, average, sum), two-dimensional code recognition, barcode recognition.

Three, mark:

Distance, X distance, Y distance, radius, diameter, angle;

4. Evaluation of shape error:

Straightness and roundness.

5. Evaluation of position error:

Parallelism, perpendicularity, symmetry, concentricity, and position.

Six, coordinate system conversion

Cartesian coordinates (X, Y) and polar coordinates (R, θ) can be easily selected. The basic unit mm, inch, mil of the measured value can be converted instantly, coordinate translation, coordinate rotation, and the workpiece coordinate system can be established.

Seven, measured data

You can customize the EXCEL template and specify the output cell. The software comes with a CPK template, which can calculate Mean, Maximum, Minimum, Cp, Cpkl, Cpku, Cpk

8. Other

1. Software language: multi-language is optional, language packs are open, and translation can be defined and modified

2. The image and drawing area are shared, what you see is what you get, can be customized: color, line width, font size, background color

3. Focus assist and light assist tools to reduce human error

4. Pass/Fail (OK/NG), and alarm prompt, voice output: OK, NG

5. The contour can be quickly scanned and exported to CAD

6. Optional IO card, external trigger measurement and OK NG signal output

9. Special customization function: customized output report, SPC data analysis function, image scanning function

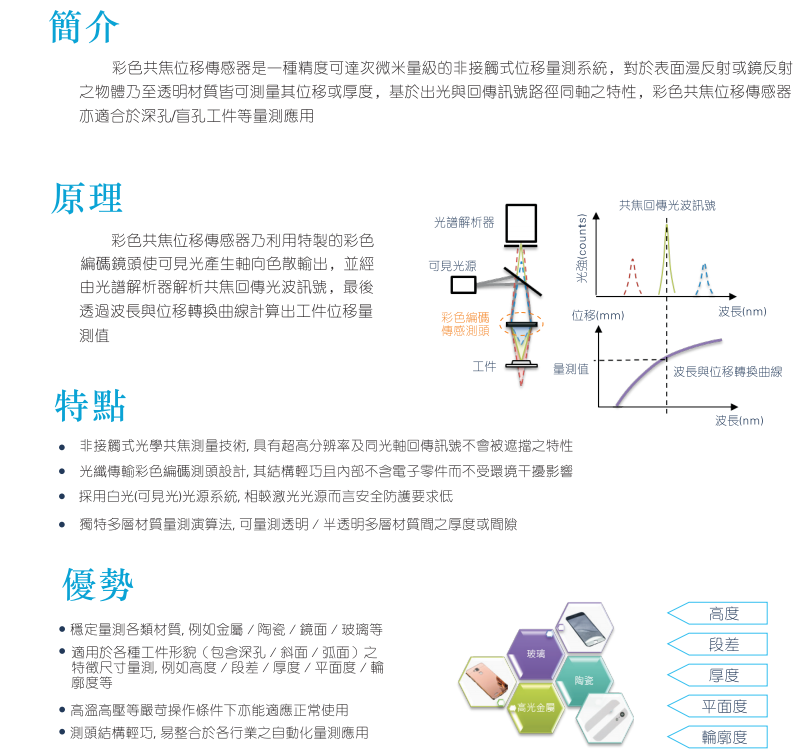

10. The color confocal measurement displacement sensor and module can measure flatness, step height and depth of blind holes, with an accuracy of 3.0μm

Application examples

1 | Host | 1 | Host | One-piece body and base (automatic splicing) |

2 | Camera system | 20 million class high-definition camera | ||

3 | Lens | Double telecentric large field of view optical lens | ||

4 | Measuring range | 86*57mm (single field of view) 86*57+20*15mm (dual field of view) | ||

5 | Measurement Accuracy | Splicing accuracy 3.0+L/200μm Single field of view accuracy 2.0μm | ||

6 | Motor | Three-axis servo motor and driver | ||

7 | Controller | Dedicated measurement controller | ||

8 | Light Source | Parallel contour light + surface light (automatic lighting and fill light) | ||

2 | Computer System | 1 | Computer | AOC computer (I7-9700/16G processor/500G/23.8 inch LCD monitor) |

3 | Software System | 1 | Basic Software | Taiwan VISION dedicated measurement software |